Accurate and long-lasting component marking is crucial in today’s fast-paced manufacturing environment. The application of identifying information, such as logos, barcodes, tracking codes, or serial numbers, to different parts and products is known as part marking, and it is an essential operation. Important for inventory management and quality control, this procedure guarantees traceability. Laser engraving is the best option for component marking since it is precise, versatile, and inexpensive compared to other methods. This article will discuss how laser engraving is changing the manufacturing business and all the benefits it offers for component marking.

Clarity and Accuracy Like Never Before

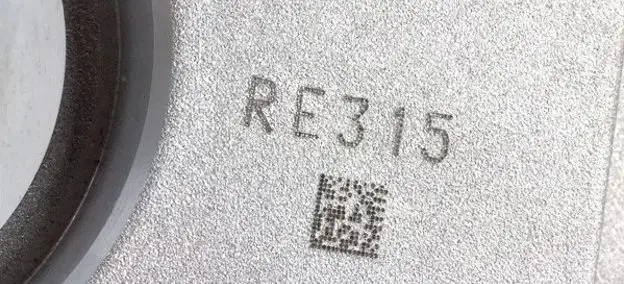

Laser engraving’s unmatched clarity and precision is one of its most notable benefits when used for component marking. Metals, polymers, ceramics, and glass are just some of the many materials that may be intricately marked with laser engraving equipment’ highly concentrated laser beams. Without touching or distorting the substance in any way, the laser beam vaporises its surface, leaving a mark that is both permanent and readable.

Even on tiny or irregularly shaped components, complex barcodes, delicate text, and high-resolution pictures may be precisely engraved with a laser. The aerospace, automotive, and medical device sectors, among others, rely on component marking applications that require this degree of precision to ensure data integrity and legibility.

Additionally, component marking is exceptionally consistent with laser engraving. Laser engraving eliminates variances caused by human mistake or ink irregularities, ensuring that each mark is equal, unlike manual marking methods or ink-based printing. When labelling big batches of components, this consistency is crucial since it ensures uniformity and makes automated data collecting and tracking operations easier.

Sturdiness and Longevity

The long-lasting and unfading nature of the marks produced by laser engraving is another major perk of using this method for component marking. Marks that are laser-engraved form a permanent part of the material, as opposed to surface-level markings like labels or ink prints. A mark that can withstand high temperatures, chemicals, and wear and tear is created when the material’s surface is physically altered by the laser beam.

Having parts that can withstand tough conditions or demanding applications is crucial. Part marking in the automobile sector, for instance, has to be able to endure vibrational stresses, high temperatures, and solvents, oils, and grease. In order to keep important information available for maintenance, repairs, and warranty purposes, laser-engraved markings stay legible throughout the part’s existence.

Additionally, laser-engraved markings are perfect for uses requiring tamper-evidence or anti-counterfeiting procedures due to their persistence. Because it is very difficult to change or remove laser-engraved markings, they give an extra degree of protection against tampering or the entry of fake components into the supply chain.

Flexibility and Material Harmony

Among the many benefits of laser engraving for component marking is its adaptability. Several materials may be used with this method. Some examples include metals (titanium, steel, and aluminium), polymers (acrylic, polycarbonate, and ABS), ceramics, and glass. Because of its adaptability, laser engraving has found widespread usage in a wide variety of product lines and industries for component marking.

The component marking procedure is made easier and less complicated with the ability to mark on numerous materials using a single laser engraving equipment. Not only does this reduce the need for operator training and maintenance expenses, but it also frees up much-needed floor space.

Marking on components with complicated geometries, curved surfaces, or inaccessible regions is also possible with laser engraving due to the material compatibility of the process. It is simpler to accept a wide range of item sizes and forms with the non-contact nature of the laser marking process, which removes the need for additional fixtures or equipment.

Quickness and Effectiveness

For high-volume manufacturing settings, laser engraving is the way to go because of how quickly and efficiently it marks parts. Laser engraving equipment provide regular cycle times and completely automate the marking process, doing away with the need for manual handling.

When compared to more conventional marking techniques like chemical etching or dot peen, laser engraving’s speed stands out. In order to meet tight production deadlines and shorten lead times, manufacturers are turning to laser engraving devices, which can make intricate markings in a flash.

Beyond the marking process itself, laser engraving is efficient in other ways as well. Because laser engraving is digital, it’s straightforward to switch between designs or batches for marking parts. Effortlessly reduce setup times and mistake rates by creating, editing, and uploading marking files to the laser engraving equipment using user-friendly software.

Efficiency and Profitability of Investment

The upfront cost of a laser engraving equipment is more than that of alternative component marking methods, but the ROI and cost-effectiveness are substantial in the long run. Faster throughput, less downtime, and lower labour costs are all results of laser engraving’s efficiency, dependability, and speed.

Save money by avoiding costly noting or part replacements caused by wear and tear thanks to the permanence and durability of laser-engraved markings. Because it helps prevent expensive recalls or legal repercussions, this durability is especially important in sectors where part traceability is crucial for regulatory compliance or warranty purposes.

Because of laser engraving’s adaptability, manufacturers may streamline their component marking processes, cutting down on the expense and hassle of maintaining and training for several marking methods. A quicker return on investment and better overall equipment effectiveness (OEE) are the results of these process optimisation efforts.

Sustainability in the Environment

Laser engraving provides a greener alternative to traditional component marking in an age when businesses are more concerned about environmental impact. Using laser engraving instead of ink-based marking or chemical etching eliminates the need for solvents and harmful compounds that might harm people and the environment.

There is very little dust and pollution produced by laser engraving because it is a dry process. Part marking activities have a less environmental effect and don’t require expensive disposal or recycling methods since they don’t use consumables like inks or chemicals.

Additionally, contemporary laser engraving equipment help minimise operational expenses and carbon footprints due to their energy efficiency. A more environmentally friendly option for component marking is laser engraving devices, which often have energy-saving settings and optimised power usage.

Data Management and Traceability

When it comes to component marking applications that require traceability and data management, laser engraving is the way to go because of its precision and durability. Manufacturers may monitor components from production to final usage by using unique identifiers like data matrix codes or serial numbers.

Businesses that must adhere to stringent quality standards and regulations, including those in the aerospace, automotive, and medical device sectors, rely on this traceability. Marks that have been laser-engraved make it possible to use scanners or vision systems to quickly and accurately collect data, which is great for automated tracking and inventory management.

Due to its digital nature, laser engraving also makes data administration and integration with ERP and MES systems more easier. The ability to save, retrieve, and update marking files makes it easy to apply the proper information to the right components at all times.

In summary

Because of its unparalleled accuracy, longevity, adaptability, and affordability, laser engraving has revolutionised the component marking industry. The use of laser engraving for component marking is expected to increase as firms place a greater emphasis on product quality, traceability, and operational efficiency.

Laser engraving allows firms to enhance product quality, cut costs, and simplify part marking operations. The versatility of the technology to produce permanent, tamper-evident markings on a variety of materials makes it a priceless asset for sectors as diverse as electronics, medical equipment, and automobiles.

Laser engraving’s advantages for component marking will grow in importance as the technology improves in terms of speed, resolution, and environmental friendliness. In an increasingly competitive market, manufacturers who use laser engraving will be able to match the changing expectations of their clients.